- TOP

- SERVICE | AMR

AMR

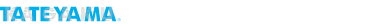

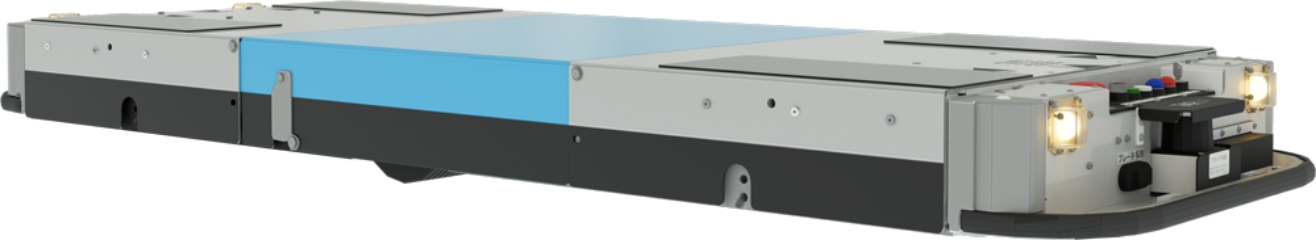

An industry-leading low height of "132mm" and a carry weight capacity of "800kg "make it ideal for transporting basket carts.

TAR is an autonomous mobile robot "AMR" that automatically conveys goods in logistics and manufacturing premises, etc. It cntributes to the automation and labor-saving of factories, and realizes factories where people and robots work together.

It can be conveyed the basket cart you currently use.

-

Achieving both

low height and

high output -

Pallet transport also

adaptablepallets can be transported as it is by introducing a compatible model with pallet transport.

-

No need to reposition the basket cart even if it is being misaligned.

No need to reposition it even if teh basket cart is misaligned as far as it will be within the set area

-

Automatic charging

functionWhen the battery level is low, it will automatically return to the charging station as "optional" and begin charging.

-

High-precision

positioning

is achievable as wellIn addition to the unique self-location estimation method, achieving highly accurate position control of both stopping and passing place by attaching magnetic tape to areas where precision is required.

(the only applicable for TAR-T02) -

Conveyance is also

feasible for basket

carts placed adjacently

(Row Grasping).Adjacent gripping/non-gripping is possible at specified locations "note there are restrictions depending on the combination of functions"

-

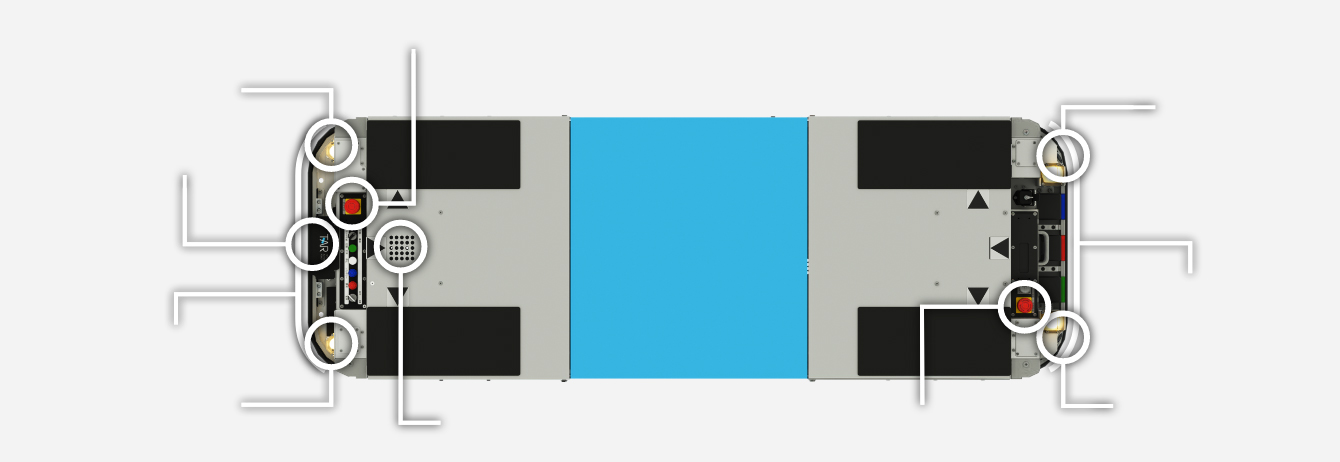

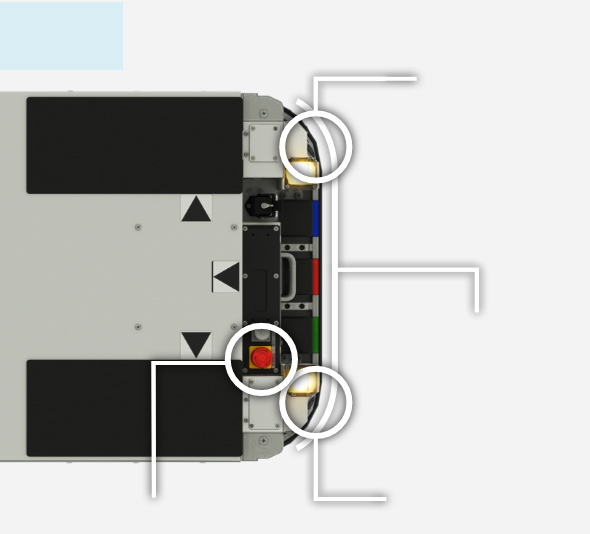

Sufficient safety equipment

To enable collaborative work with humans, the TAR is equipped with a full range of safety characteristic, including the ability to detect and stop people and obstacles, as well as warning functions using turn signals and speakers, and bumper sensors to detect contact.

Front

Emergency stop switch

Lamp with turn signals

LiDAR sensor

Bumper Sensor

Lamp with turn signals

Speaker

Back

Ultrasonic Sensor

Bumper Sensor

Ultrasonic Sensor

Emergency stop switch

-

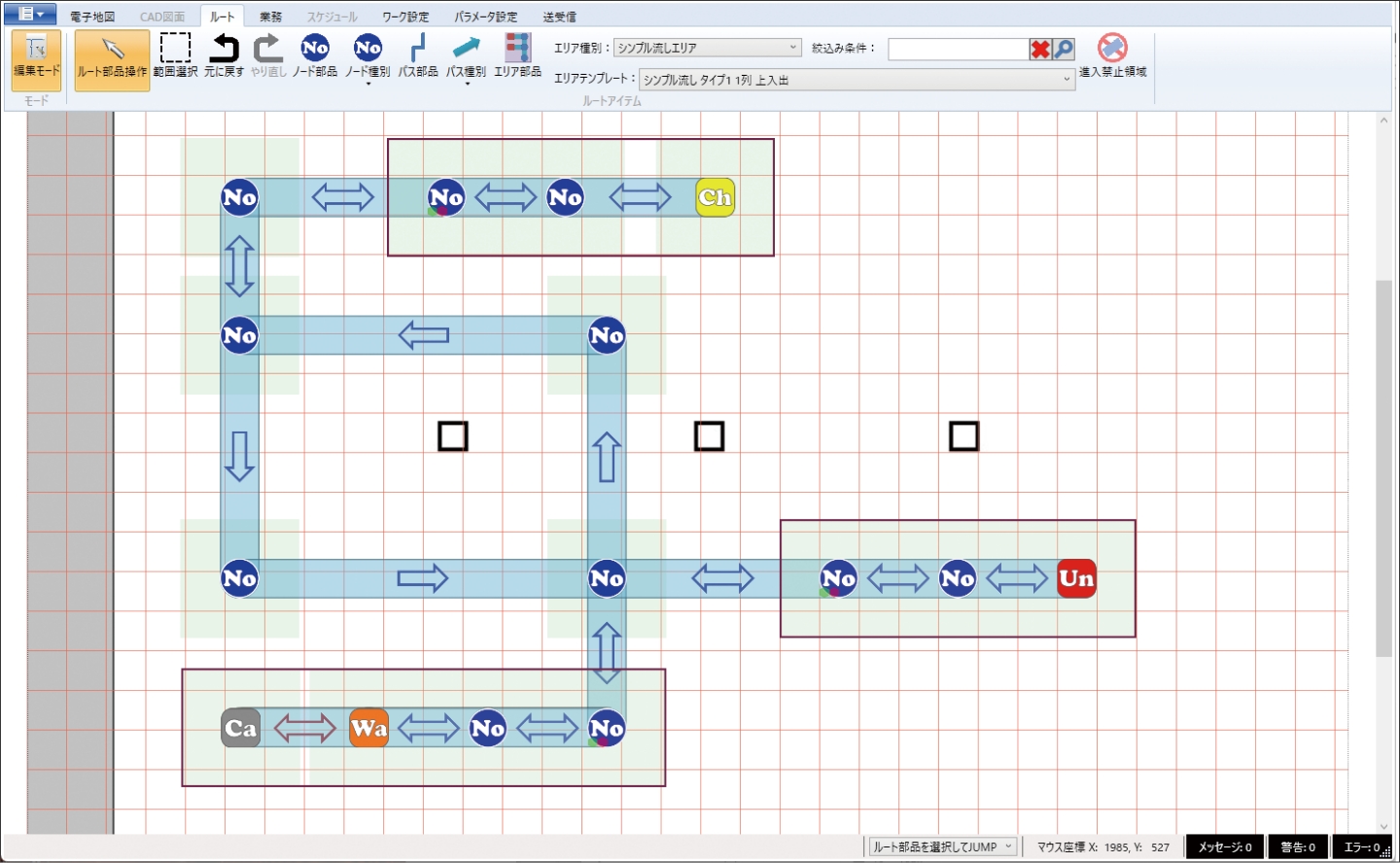

AMR route

creation toolEasily create AMR driving routes with intuitive operations

Route creation tool featuring user-

friendly UIEasy operation for route and layout changes is also available

-

-

Requirement

definition -

Design

&

Manufacturing -

Installation

-

Maintenance

One-stop solution

We provide one-stop with consistent, in-house customization services from requirements definition until design, manufacturing, installation, and maintenance.

-

-

Pre-implementation support

The system can be verified in advance by executing a proof of concept (PoC) using an actual AMR device when considering its introduction.

Specialized staff will provide comprehensive operation and training during the installation of the equipment.

-

Maintenance services

We provide the following maintenance services to ensure you can use our products for a long time with confidence.

Implementing Preventive maintenance by acquiring

LIFEDATA* Maximize MTBF (Mean Time Between Failures).Regular inspection of an autonomous mobile robot (once a year)

Cleaning, oiling, and replacing work for consumable parts such as running parts

Comprehensive inspection by using safety inspection and dedicated verification software

*LIFEDATA:Accumulated data stored inside the TAR main unit in use

The information desk

Providing information to ensure you use the product with confidence

Recovery support when an error or other incident occurs

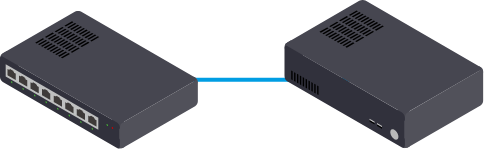

System

configuration

example

-

Explanatory notes:

-

LAN cable(STP)

-

Wireless LAN

-

Application

Operation terminal

Route creation tools

-

Middleware

Server

AMR group control system

MES/WCS

Existing

SystemSystem linkage

-

Network

Wireless LAN Access Point

Power supply

hubWireless LAN

Controller -

Robot

AMR

Charger

Automatic

charging

(Optional)

Product specifications and designs are subject to change

without notice in advance for improvement purposes.

Case studies and achievements

Loading and unloading of the logistics warehouse

Without magnetic tapes or QR codes, luggage is automatically delivered at the specified time along the specified route

This is enable to reduce the number of people required for works such as moving delivered goods to designated locations within the warehouse.

Carry-in entrance

Automatically picks up delivered luggage and transports it to the designated location

Once the load is unloaded, the robot automatically returns and begins transporting loads again.

Warehouse

Automatic carriage and sorting in logistics warehouses

Basket carts equipped with RFID tag automatically sort items into their designated destinations.

It can be freely changed the destination settings to be delivered and layout.

-

Automatic sorting

to

the locations to

be deliveredUnmanned

transportation utilizes

RFID technology during

delivery. -

Freely change the transport route

Delivery routes and

layouts can be changed

on a PC -

Identification methods other than

RFID also can be accommodatedProposal for identification

method well suited to the

factory and equipment.

-

A worker attaches an

RFID tag to a basket cart -

The system reads through the

RFID tag on the basket cart -

AMR delivers to each

storage location

-

RFID tags linked to

sorting destinations -

Display for the

sorting destinations

so that everyone

can understand

Manufacturing process transport

Unmanned connection between work processes

The fixed movement of items, such as handing over parts to the next process, can be automated without the introduction of fixed equipment such as conveyor belts, and can flexibly accommodate layout changes.

It is also possible to operate unmanned at set times.

Items can be delivered automatically even at night or during break times when staff are not present, allowing work schedules to proceed efficiently.

work process A

Delivery A's items to the next process at the appointed time

Once the goods are unloaded at process B, the machine automatically returns to process A and delivers the goods again.

work process B

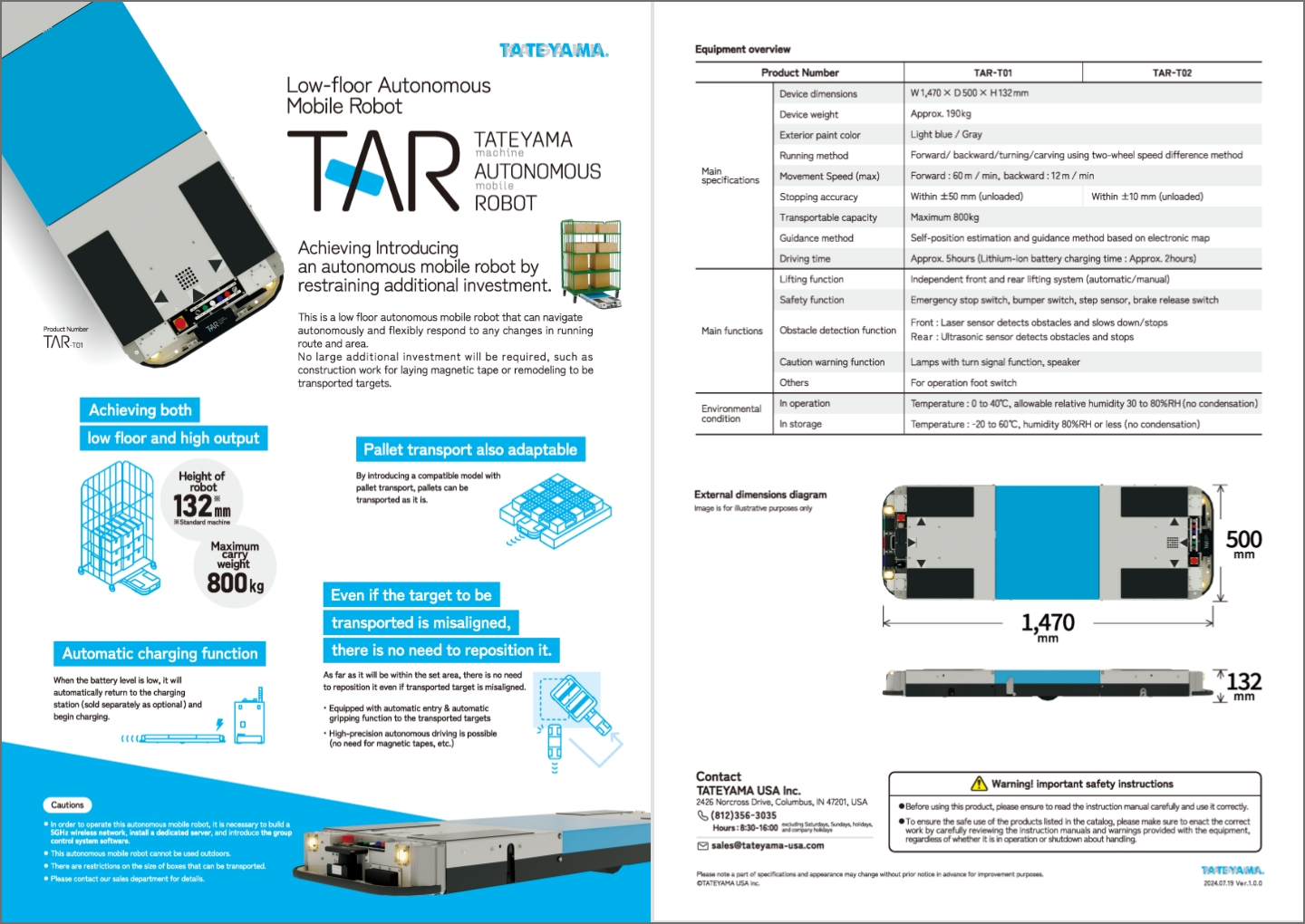

Specification

Equipment Specifications

Product number

TAR-T01

TAR-T02

Main

specifications

Device dimensions

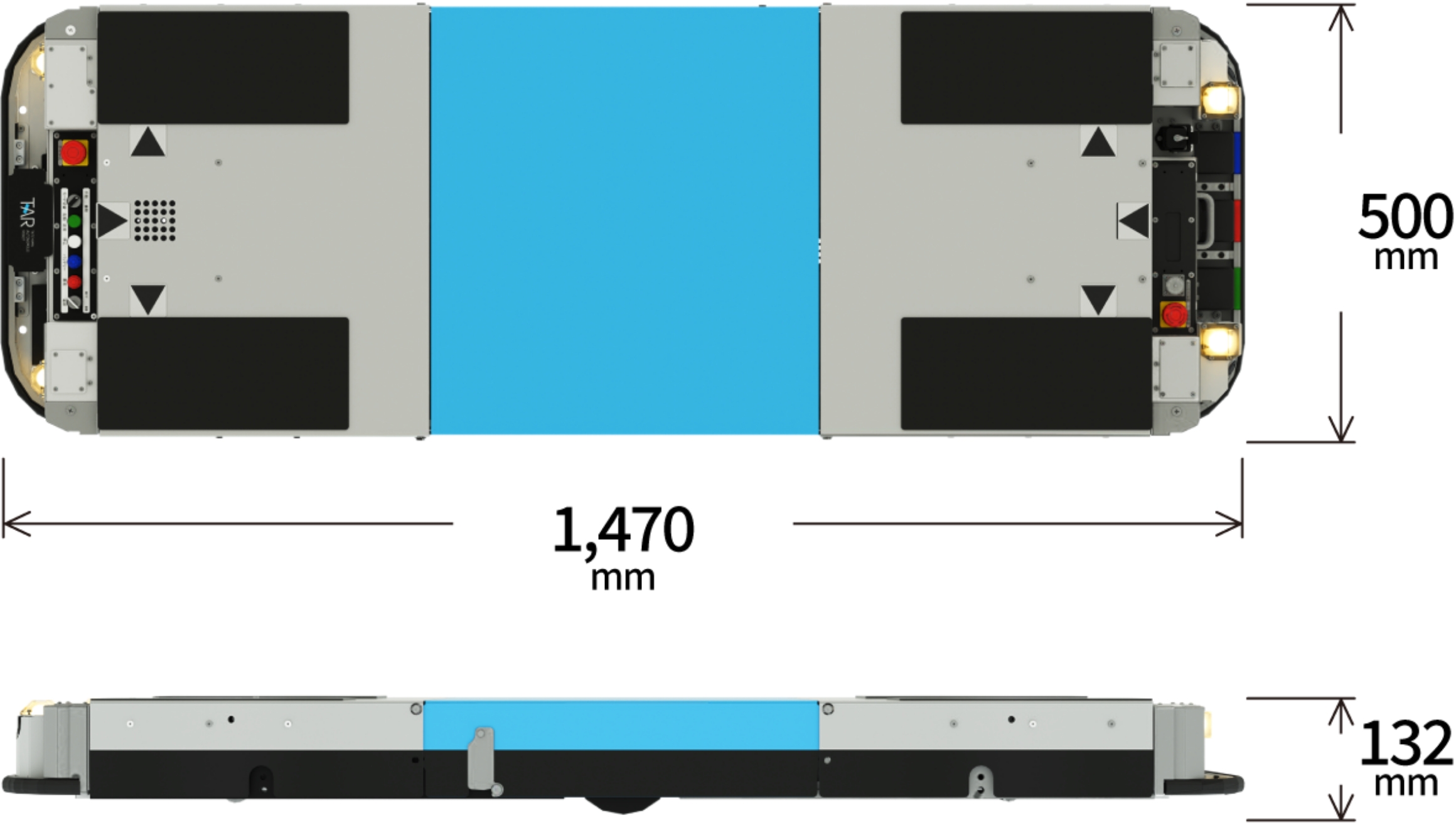

W 1,470 × D 500 × H 132 mm

Device weight

Approx.190kg

Running method

Forward/ backward/turning/carving using two-wheel speed difference method

Movement Speed (max)

Forward: 60 m/min, backward: 12 m/min

Stopping accuracy

TAR-T01±Within 50 mm (unloaded)

TAR-T02±Within 10 mm (unloaded)

Transportable capacity

Maximum 800 kg

Guidance method

Self-position estimation and guidance method based on electronic map

Driving time

Approx. 5 hours (Lithium-ion battery charging time: Approx. 2 hours)

Main functions

Safety function

Emergency stop switch, bumper sensor, step sensor, brake release switch

Obstacle detection

function

Front:

slows down/stops by Laser formula sensor obstacles detection

Rear:

stops by Ultrasonic sensor formula obstacles detection

Caution warning

function

Lamp with turn signal function, speaker

In operation

Temperature: 0 to 40°C, allowable relative humidity 30 to 80%RH (no condensation)

In storage

Temperature: -20 to 60°C, humidity 80%RH or less (no condensation)

External dimensions

Image is for illustrative purposes only

TAR Flyer

Top Frequently Asked Questions

-

Can it be used on a trial basis?

It is possible to actually bring AMR to your environment and check it in advance (fees apply).

-

How many types of size for AMR are there?

Currently, there is only one size of AMR, but the size will vary depending on the various options.

-

Is it possible to operate AMR outdoors ?

This product is intended for indoor use and is not appropriate for outdoor environments.

-

How wide does the aisle need to be?

The specifications state that 1,800 mm is required, but this depends on the conditions. Please contact us for details.

-

How well does it handle bumpy floor surfaces, slopes and trenches ?

The specifications are able to accommodate with steps of 5 mm or less, slopes of 1 degree or less, and trenches widths of 10 mm or less.

-

Is it possible to drive on gratings?

Generally, we do not recommend it. However, depending on the type of grating, it may be possible, so please contact us for more information.

-

Can it be used in a clean room?

It cannot be used in clean rooms.

-

How do I charge to the battery?

You can charge it at any time with the manual charger, or you can have it charge automatically (optional) depending on the remaining power.

-

Is there any way to check the battery deterioration and lifespan?

When it is time to replace the battery, an error code will be displayed on the unit.

-

Can it be used in a freezer storage?

The product is designed for use in environments of 0°C or above and is therefore unsuitable for freezer storage.

-

How do we go about obtaining an electronic map?

An electronic map of the operating area can be obtained by manually driving the AMR unit.

-

Is it possible to operate across floors?

Currently, it is not possible to operate across floors.

cautions

-

In order to operate this autonomous mobile robot, it is necessary to build a 5GHz wireless network, install a dedicated server, and introduce the group control system software.

-

This autonomous mobile robot cannot be used outdoors.

-

There are restrictions on the size of basket cart that can be transported.

-

Please contact our sales department for details.